Factory For “Cable Filling Compound ” - G655 Single-mode optical fiber – GELD

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Factory For “Cable Filling Compound ” - G655 Single-mode optical fiber – GELD Detail:

DOF-LITETM (LEA) is ideal for high data-rate, multi-wavelength long haul transmission. It has a large efective area for improved power handling plus dispersion optimized for dense wavelength division multiplexing (DWDM). It is suitable

for transmission in the conventional C-band (1530-1565 nm) and L-band (1565- 1625 nm). DOF-LITETM (LEA) exceeds the requirements of today’s high- channel-count 2.5 Gb/s and 10 Gb/s systems, and supports migration to next generation 40 Gb/s data rates.

DOF-LITETM (LEA) has a large efective area for improved power handling plus dispersion optimized for dense wavelength division multiplexing (DWDM). This combination reduces the onset of non-linear transmission efects such as four-wave mixing and self-phase modulation, whilst also reducing the cost and complexity of dispersion compensation.

| Attenuation | ≤ 0.22 dB/km at 1550 nm/ ≤ 0.24 dB/km at 1625 nm |

| Mode field diameter at 1550 nm | 9.6 ± 0.4 µm |

| Cable cutoff wavelength | ≤ 1450 nm |

| Dispersion slope at 1550 nm | ≤ 0.09 ps/nm2.km |

| Dispersion at 1460 nm | -4.02 to 0.15 ps/nm.km |

| Dispersion at 1530 nm | 2.00 to 4.00 ps/nm.km |

| Dispersion at 1550 nm | 3.00 to 5.00 ps/nm.km |

| Dispersion at 1565 nm | 4.00 to 6.00 ps/nm.km |

| Dispersion at 1625 nm | 5.77 to 11.26 ps/nm.km |

| Fiber polarization mode dispersion link design value* | ≤ 0.15 ps/√km |

| Cladding diameter | 125.0 ± 1.0 µm |

| Core-clad concentricity error | ≤ 0.5 µm |

| Cladding non-circularity | ≤ 1.0 % |

| Coating diameter (uncolored) | 242 ± 5 µm |

| Coating-cladding concentricity error | ≤ 12 µm |

| * Individual PMD values may change when cabled | |

| Proof Test Levels | ≥ 100 kpsi (0.7GN/m2). This is equivalent to 1% strain |

| Coating strip force(Force to mechanically strip the dual coating) | ≥ 1.3 N (0.3 lbf) and ≤ 5.0 N (1.1lbf) |

| Fibre curl | ≥ 4 m |

| Macro bend loss: The maximum attenuation with bending does not exceed the specied values with the following deployment conditions | |

| Deployment condition | Wavelength | Induced attenuation |

| 1 turn, 16 mm (0.6 inch) radius | 1625 nm | ≤ 0.50 dB |

| 100 turns, 30 mm (1.18 inch) radius | 1625 nm/ 1550 nm | ≤ 0.10 dB/ ≤ 0.05 dB |

| Temperature dependence Induced attenuation, -60°C to +85°C at 1550, 1625 nm |

≤ 0.05 dB/km |

| Temperature humidity cycling Induced attenuation, -10°C to +85°C and 95% relative humidity at 1550, 1625 nm |

≤ 0.05 dB/km |

| High temperature and humidity aging 85°C at 85% RH, 30 days Induced attenuation at 1550, 1625 nm due to aging | ≤ 0.05 dB/km |

| Water immersion, 30 days Induced attenuation due to water immersion at 23±2°C at 1550, 1625 nm |

≤ 0.05 dB/km |

| Accelerated aging (Temperature), 30days Induced attenuation due to temperature aging at 85±2°C at 1550,1625 nm |

≤ 0.05 dB/km |

| Effective group index of refraction | 1.470 at 1550 nm |

| Attenuation in the wavelength region from 1525 - 1575 nm in reference to the attenuation at 1550 nm | ≤ 0.05 dB/km |

| Point discontinuities at 1550 nm & 1625 nm | ≤ 0.05 dB |

| Dynamic fatigue parameter (Nd) | ≥ 20 |

| Effective area | 70 µm 2 |

| Weight per unit length | 64 gm/km |

| *Typical values | |

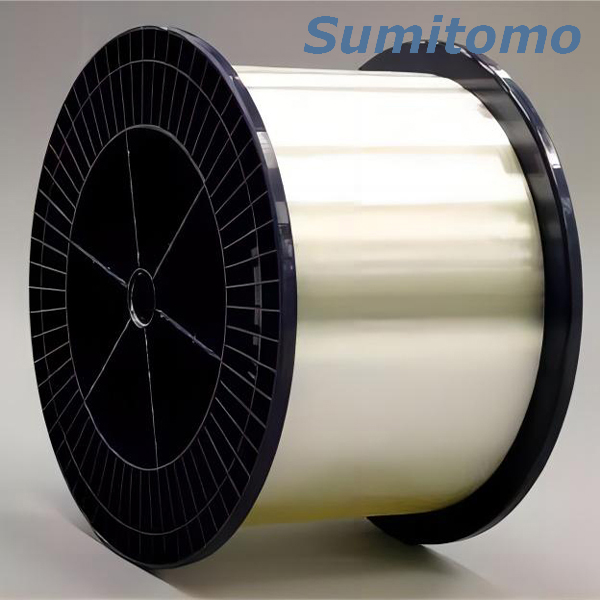

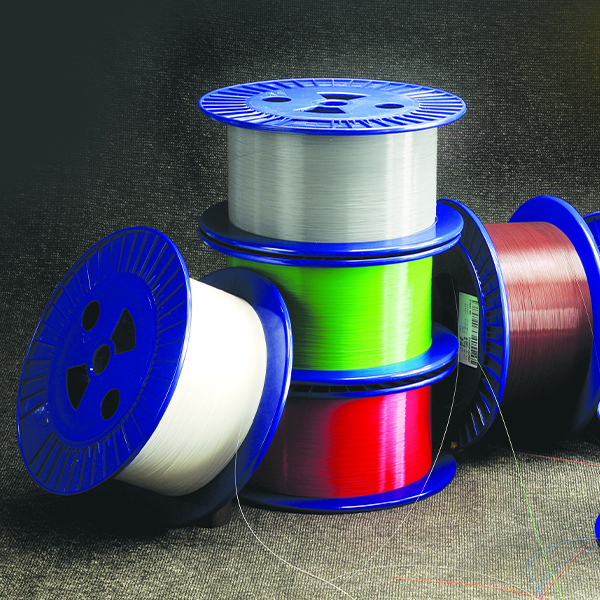

| Shipping spool flange diameter | 23.50 cm (9.25 inches) or 26.5 cm (10.4 inches) |

| Shipping spool barrel diameter | 15.24 cm (6.0 inches) or 17.0 cm (6.7 inches) |

| Shipping spool traverse width | 9.55 cm (3.76 inches) or 15.0 cm (5.9 inches) |

| Shipping spool weight | 0.50 kg (1.36 lbs) or 0.88 kg (1.93 lbs) |

| Shipping length: standard length per reel available up to 25.2 km. lengths per reel as per customer request is also available | |

We controls every stage of the manufacturing process so that quality is built in to every meter of fibre, rather than selected out at the end through testing. To ensure the accuracy and precision of the manufacturing process, we routinely calibrates and recertifies process equipment and measurement benches against internationally traceable standards from NPL/NIST, and follow test methods compliant with EIA/TIA, CEI-IEC and ITU standards.

The DOF-LITETM (LEA) ccomplies with ITU-T G655 C & D Optical Fiber Specification.

● Complete range of optical fibre for terrestrial networks

● World-wide sales support

● Web-based order tracking & customer support Specialized technical support

Our company’s policy of continuous improvement may result in a change in specifications without prior notice. Any warranty of any nature relating to any of our product is only contained in the written agreement between our company and the direct purchaser of such product(s).

Product detail pictures:

Related Product Guide:

Our goal is to satisfy our customers by offering golden service, good price and high quality for Factory For “Cable Filling Compound ” - G655 Single-mode optical fiber – GELD , The product will supply to all over the world, such as: The Swiss, Nicaragua, Florence, We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.

Products categories

-

Discount wholesale lc to sc adapter - Small-re...

-

Factory For Optical Sleeve Case - Wire Cable T...

-

Manufacturer for single mode fiber - Secondary...

-

Factory Free sample Optical Fiber Cable Connect...

-

OEM Supply fiber cable types - Polyamide R...

-

Top Suppliers fibre connection box - Dipped co...