Good Quality “Extrusion Process ” - G.652D Single-mode optical fiber (B1.3) – GELD

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

Good Quality “Extrusion Process ” - G.652D Single-mode optical fiber (B1.3) – GELD Detail:

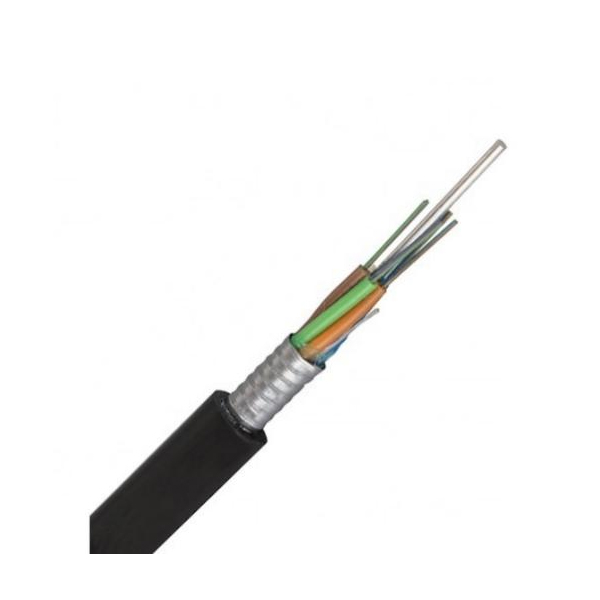

1. Suitable for all kinds of fiber optic cable structure: central beam tube type, loose sleeve layer stranded type, skeleton type, fiber optic cable structure;

2. Applications of optical fiber include: fiber optical systems requiring low loss and high bandwidth, such as long-distance communication, trunk lines, loop feeders, distribution lines and cable TV, etc., especially suitable for 1383nm band coarse wavelength division multiplexing (CWDM), dense wavelength division multiplexing (DWDM) and various special environment use (e.g. Lightning-proof OPGW optical cable, ADSS optical cable, etc.), the optical fiber through special light curing coating material and coating process and after processing, so that it has a more superior performance in mechanical properties and high temperature environmental performance.

|

Project |

Standards or requirements |

Unit |

||||

|

Optic loss |

1310nm |

≤0.35 |

(dB/km) |

|||

|

1383nm |

≤0.33 |

(dB/km) |

||||

|

1550nm |

≤0.21 |

(dB/km) |

||||

|

1625nm |

≤0.24 |

(dB/km) |

||||

|

Attenuation wavelength characteristic(dB/km) 1285nm~1330nm relative to 1310nm 1360nm~1410nm relative to 1383nm 1525nm~1575nm relative to 1550nm |

≤0.03 ≤0.05 ≤0.02 |

(dB/km) (dB/km) (dB/km) |

||||

|

Dispersion |

1288nm~1339nm |

∣D∣≤3.4 |

(ps/nm.km) |

|||

|

1271nm~1360nm |

∣D∣≤5.3 |

(ps/nm.km) |

||||

|

1550nm |

≤17.8 |

(ps/nm.km) |

||||

|

Zero dispersion wavelength

|

1300~1322 |

(nm) |

||||

|

Zero-Dispersion Slope

|

≤0.091 |

(ps/.km) |

||||

|

Polarization mode dispersion |

PMD single fiber |

≤0.15 |

(ps/) |

|||

|

PMDQ link |

≤0.08 |

(ps/) |

||||

| Mode field diameter |

1310nm |

9.2±0.4 |

|

|||

|

Mode field diameter |

125±1.0 |

(μm) |

||||

|

Cladding non-circularity |

≤0.8 |

(%) |

||||

|

Core/packet concentricity error |

≤0.6 |

(μm) |

||||

|

Secondary coating diameter |

245±10 |

(μm) |

||||

|

Packet/coating concentricity error |

≤10.0 |

(μm) |

||||

|

Cutoff wavelength |

1.18~1.33 |

(μm) |

||||

|

Macro bending attached attenuation

|

Φ50mm 100 laps |

1550nm 1625nm |

≤0.05 |

(dB) |

||

|

≤0.05 |

(dB) |

|||||

|

Bending radius |

≥5 |

(m) |

||||

|

Dynamic fatigue parameter |

≥20 |

() |

||||

|

Decay temperature characteristic(-60℃~85℃ 3 times recycle) |

1310nm 1550nm |

≤0.03 |

(dB/km) |

|||

|

Flooding performance(Soak in water at 23℃ for 30 days) |

≤0.03 |

(dB/km) |

||||

|

Humidity and heat performance (85℃ and 85% for 30 days) |

≤0.03 |

(dB/km) |

||||

|

Thermal aging performance (30 thermal aging performance at 85℃ (30 days at 85℃) |

≤0.03 |

(dB/km) |

||||

|

Warm water test (soak in 60℃ water for 15 days) |

≤0.03 |

(dB/km) |

||||

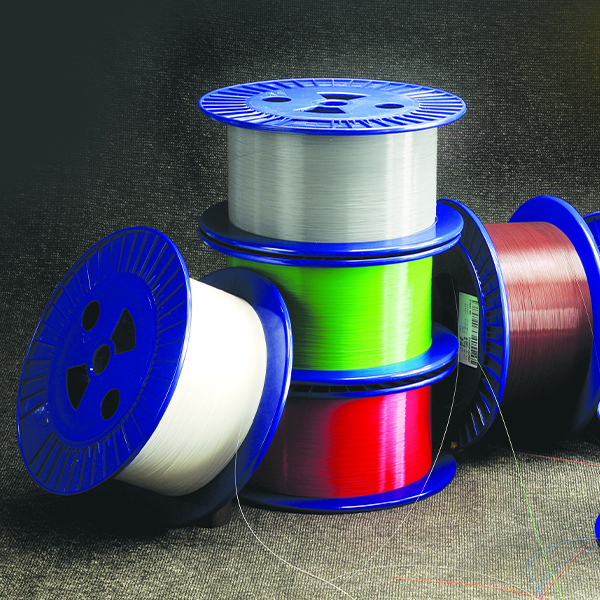

Product detail pictures:

Related Product Guide:

Innovation, quality and reliability are the core values of our company. These principles today more than ever form the basis of our success as an internationally active mid-size company for Good Quality “Extrusion Process ” - G.652D Single-mode optical fiber (B1.3) – GELD , The product will supply to all over the world, such as: Rome, Uzbekistan, Mexico, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

We have worked with many companies, but this time is the ,detailed explanation, timely delivery and quality qualified, nice!

Products categories

-

Waterproof Patch Cord Outdoor Optical cable cr...

-

Adjustable Pole Mounting Cable Hoop – GELD

-

Special Design for underwater fiber optic cable...

-

Special Price for fiber optic patch cable - La...

-

Ftth Fiber Optic Distribution Box Fiber Optic ...

-

OEM Supply Sz Stranding Production Line - Cabl...