One of Hottest for use of optical fibre - Optical fiber filling Jelly – GELD

Short Description:

Product Detail

Product Tags

Related Video

Feedback (2)

One of Hottest for use of optical fibre - Optical fiber filling Jelly – GELD Detail:

The non-Newtonian nature allows the jelly to thin out during processing and set after the processing shear forces are removed. Critical parameters that impart the necessary performance are viscosity at various shear rates and the yield stress. Typically the jelly is made using oil and an inorganic or organic thickener. Inorganic thickeners used range from organic clays to silica. These thickeners are suspended in a hydrophobic oil such as a mineral oil or synthetic oil. Additionally, stabilizers may be incorporated to ensure oxidative stability of the mixture.

● XF-400 is compatible with acrylic resin coatings and polymer materials for fiber and cable applications.

● It is recommended that all polymer materials in contact with the paste be tested for compatibility during use.

● The XF-400 is designed for a cold fill process that avoids voids due to paste shrinkage.

|

Parameter |

Representative Value |

Test Method |

|

Appearance |

Colorless and Semitransparent |

Visual inspection |

|

color stability@ 130°C / 120hrs |

<2.5 |

ASTM127 |

|

density (g/ml) |

0.83 |

ASTM D1475 |

|

flashing point (°C) |

> 200 |

ASTM D92 |

|

dropping point (°C) |

>200 |

ASTM D 566-93 |

|

penetration @ 25°C (dmm) |

440-475 |

ASTM D 217 |

|

@ -40°C (dmm) |

>230 |

ASTM D 217 |

|

viscosity (Pa.s @ 10 s-1 25°C) |

4.8+/-1.0 |

CR Ramp 0-200 s-1 |

|

(Pa.s @ 200 s-1 25°C) |

2.6+/-0.4 |

CR Ramp 0-200 s-1 |

|

oil separation @ 80°C / 24 hours (Wt %) |

0 |

FTM 791(321) |

|

volatility@ 80°C / 24 hours (Wt %) |

<1.0 |

FTM 791(321) |

|

oxidation induction time(OIT)@ 190°C (min) |

>30 |

ASTM 3895 |

|

acid value (mgKOH/g) |

<0.3 |

ASTMD974-85 |

|

Hydrogen evolution amount 80°C/24hours(µl/g) |

<0.02 |

|

|

water-resistance (20°C/7days) |

pass |

SH/T0453a |

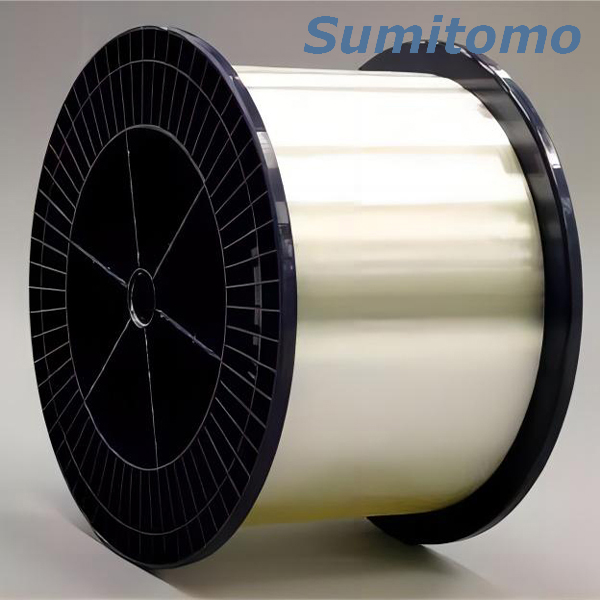

Product detail pictures:

Related Product Guide:

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for One of Hottest for use of optical fibre - Optical fiber filling Jelly – GELD , The product will supply to all over the world, such as: Iran, Albania, Morocco, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to provide our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

In China, we have many partners, this company is satisfying to us, reliable quality and good credit, it is worth appreciation.

Products categories

-

China Supplier fiber optic light source - Non-...

-

High Quality for fiber optic splicer - Water B...

-

Fiber Optic Patch Cord ODF unit box – GELD

-

Top Suppliers fibre connection box - G655 Sing...

-

New Fashion Design for single mode sfp - Singl...

-

Ordinary Discount Tension Flat Cable Clamp - W...